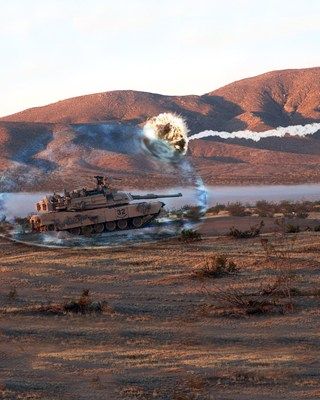

US Army recognises many different means of active protection

Business development teams in the US and overseas may be well served by placing or retaining this fast-moving US Army programme on their project calendars.

The US Army’s Modular Active Protection System (MAPS) is a multi-year Research, Development and Engineering Command public-private programme led by US Army Tank Automotive, Research, Development and Engineering Center (TARDEC), worked in collaboration with the acquisition community and an increasing number of industry partners. MAPS will deliver two main products: a Modular Active Protection System Framework, that will standardise the way any active protection system or vehicle protection system is fielded; and a MAPS Base Kit consisting of a Modular APS controller, a central processing resource that manages the platform interface along with a sensor and countermeasure capabilities, and other components.

Paul Rogers, PhD, Director of TARDEC, added MAPS also includes, “very well-defined protocols and standards for communication, and we embed that inside the vehicle. It represents the architecture inside the vehicle that allows us to more quickly post different protection technologies onto the vehicle.”

The US Army recognises many different means of active protection (hard kill and soft kill) for a vehicle, some of which include: countermeasures, to intercept an incoming threat; soft kill, to jam or spoof the hostile force’s aim point; a “revenge kill” – a slew to cue, if you will, where your weapon system fires at the target that engaged you; and many others. The army subject matter expert continued: “As we continue to develop these solutions for different threats, having the modular architecture on the vehicle allows us to more easily apply those different countermeasures more rapidly and more affordable.”

The first step in fielding MAPS, is providing the common Modular APS controller that will be placed in every vehicle requiring an active defence capability. Lockheed Martin is developing the Modular APS controller, and other hardware components of an evolving MAPS Base Kit. “Our goal is to design that ‘box’ [controller] and architecture standards, and be able to demonstrate that we can interact with a hard kill solution from a variety of vendors or a soft kill solution with a variety of technologies, and be certain that architecture and accompanying data is owned by the US Army,” Steven Botwinik, Lockheed Martin’s Director of Sensors and Global Sustainment Advanced Programs, said.

Lockheed Martin delivered five MAPS controllers to TARDEC in 2017.

Further, during AUSA Global Force Symposium & Exposition, TARDEC awarded Lockheed Martin a next-phase contract to continue maturing the MAPS controller base kit hardware and software and to support government integration efforts ahead of platform demonstrations scheduled to take place through 2019.

An expanding industry effort, beyond Lockheed Martin’s role, supports MAPS. An approximate 45-member industry consortium, is actively helping the army design MAPS. “They are doing the physical building and work on it,” Dr. Rogers said. “All of these companies have access to, and have a say in: how we establish our standards and protocols; what kind of messaging; and what goes in and out of the box [Modular APS controller]. What is so important about that is those approximate four dozen companies make some sort of objective piece of the system. Their participation ensures the controller properly communicates with what they are building.”

The consortium is a watershed change in acquisition management in this sector. In the past, a single company or single team of companies would sell an entire, proprietary system to the US Army. System upgrades were accomplished by the army contracting on a case-by-case basis with the equipment manufacturer.

As significant, MAPS is a true international effort. In one instance, Rafael is working with the US Army to modify its TROPHY system to be MAPS compliant.

Dr. Rogers reiterated the collaborative nature of MAPS and noted: “My goal for the army is we have any number of hard kill systemmes that work. And any number of soft kill systemmes that work. I want to have a whole assembly of different capabilities because each vehicle, because of its inherent armour protection, requires a different type of active solution to optimise its survivability.”

The service-industry team is in the phase of maturing its interface to the expedited hard kill mechanism. The pace of other activities is increasing.

This June-July, TARDEC will sponsor a “Soft Kill Rodeo” at US Army’s Redstone Test Center, Redstone Arsenal, Alabama. The army has invited industry soft kill suppliers to attend and demonstrate their products. The army official added: “We’ll down select and choose that soft kill system that will be part of a 2019 layered demonstration.”

That 2019 demonstration will convene under the sponsorship of the service-industry team, with the intent to demonstrate that soft kill capability and a to-be-determined hard kill capability “layered on top.”

The US Army representative for responding to industry queries about MAPS may be contacted here.

Marty Kauchak