Contributed Content – Edited for Style and Length

Modern, complex aircraft – like the NATO NH90 helicopter – reduce pilot workload by employing high-tech solutions. A flight control computer interprets pilot commands and ensures that the aircraft performs the commanded manoeuvres. Elaborate computers monitor aircraft systems in flight, only highlighting issues to the flight crew when threshold parameters are exceeded. This level of complexity imposes new challenges on the training of ground crews.

It has been common practice that, whenever an operator fields a fleet of aircraft, one or more of these aircraft is allocated to ground crew training, resulting in the operational fleet always being one or more aircraft short. Additionally, flight equipment design focuses on light weight, and is built for a limited number of flight hours and exchange cycles. This usually results in considerable demand for spares and repairs from the training community. Since the spares are original aircraft equipment, both training and operational teams compete for the limited resources available: it is not hard to imagine who wins most often.

Reiser Simulation and Training GmbH (RST) conducted a Training Needs Analysis, and proposed the use of full-scale replica training devices for ground crew training. The company refers to the full-scale replica of a complete helicopter as the Maintenance Training Rig (MTR), while smaller training devices, catering only for components of the aircraft, are designated Part Task Trainers (PTT).

Despite being high-fidelity replicas, these devices are designed and built for 24/7 hands-on training operation, with a lifetime of at least 30 years. The MTR concept solves the challenges described above by providing high-end training capabilities without affecting fleet numbers. As the MTR is a different design, there is no competition for spare parts between training and flight operations, should one of the replicated items need replacement.

Using an original aircraft for training purposes usually comes with additional comprehensive tasking to ensure and maintain flight-ready status. Prior to every training session, drainage of oil, hydraulic system pressure release, or fuel and cooling fluids draiange are tedious and time-consuming tasks. Despite having the same fidelity, the MTR is based on ‘dry’ systems, allowing training to start immediately, maximising training efficiency while ensuring environmental protection. This also increases occupational safety by having an isolated training environment.

MTRs and PTTs are designed training line maintenance skill levels based on DEMAR 66 CAT A, CAT B1 and CAT B2. The following skills can be trained:

- Original Equipment Manufacturer (OEM) maintenance instructions usage

- Mechanical system familiarisation and handling

- Electrical system familiarisation and handling

- Avionic system familiarisation and handling

- Weapon and safety system familiarisation and handling

- Checking aircraft system function via e.g. control tests and built-in tests

- Fault isolation and correction

Experience shows that initial procurement costs are 50-70% less than the alternative of using a ‘live’ aircraft – realised without any compromise in the high fidelity representation of maintenance procedures. Continuous training is achieved by using mass consumable items from spares stock, which keeps consumables permanently available for training – independent of the original aircraft supply chain.

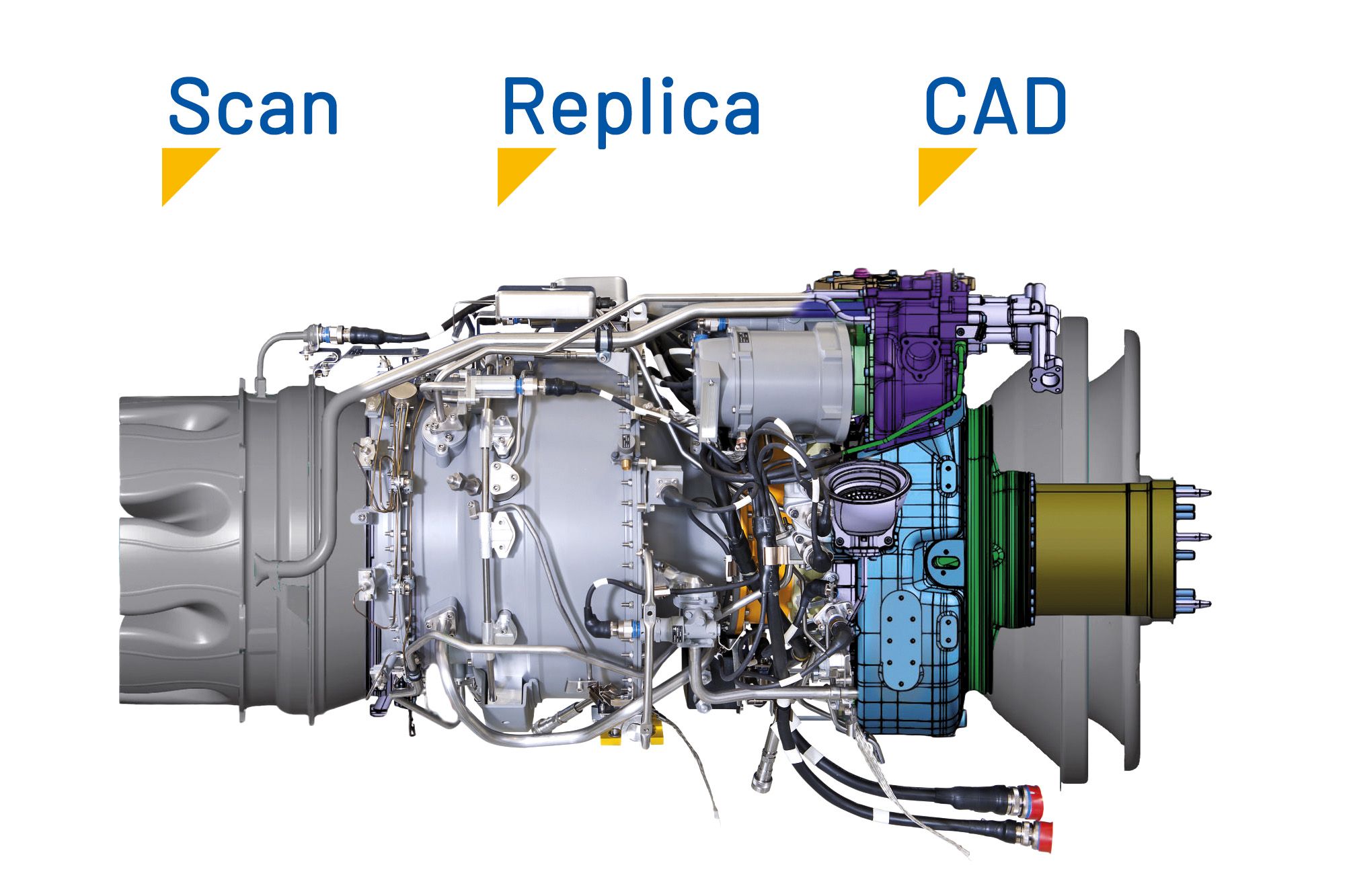

The MTR design does not necessarily rely on OEM data. The successful NH90 MTR design concept is based on an in-house data-gathering process, performed on original aircraft, using a wide range of technologies from manual data-gathering to high-resolution 3D scanning. This unique data-gathering and design approach can be applied to any platform, be it a military transport aircraft like the A400M or a modern start-of-lifecycle airliner.

Today, technical capabilities and regulations change very rapidly. As a result, maintenance organisations face the challenge of keeping up to date with an ever-changing environment. To meet the challenge, a wide range of upgrade potential comes with the modular MTR and PTT concepts. New technical capabilities on the original reference aircraft can be easily upgraded on the MTRs and PPTs. Even a fully simulated cockpit can be added at a later stage, allowing pilots to gain avionics familiarisation, or maintenance personnel to become familiar with failure tracking.

Based on the MTR and PTT designs, products such as cabin simulators, exit trainers or hoist trainers can be derived, in order to expand flight crew training. On request, RST is able to use the same data to develop Virtual Reality Maintenance Trainers and Augmented Reality Interactive Procedure Trainers.