Australia’s Minister for Defence Industry officially unveiled on 11 June Supashock’s Automatic Load Handling System fitted to a Rheinmetall MAN Military Vehicles HX 8×8 truck

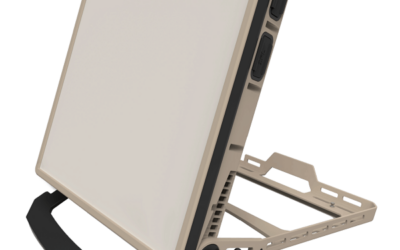

Dubbed ALHS 17, the new innovative load handling system offers the capability of automated loading and unloading of ISO containers, modules, and STANAG-complient flat racks weighing up to 17 t from inside the highly protected truck cabin. Designed and built by Adelaide-based Supashock, the concept is about to revolutionise load handling systems for military applications. An automotive technology firm, Supashock became part of Rheinmetall‘s global corporate network, with the company holding a 49% stake in the Australian firm. Minister for Defence Industry Christopher Pyne MP stated that Rheinmetall is becoming a very significant partner with the Australian Government, with the ADF (Australian Defence Force) and the Department of Defence, for developing a very significant capability. He continued that Rheinmetall will deliver the combat reconnaissance vehicles to be built in Australia in a AUD5.2 billion acquisition programme. As both the government administration and policy changed, he underlined, some AUD200 billion will be spent over the next ten years.

“We wanted to give as much as Australian content into these big projects. We will have probably never the chance again in the next few decades to have so many significant positions in really big projects and that will give us the chance to create an Australian industry for sophisticated, highly technically proficiently, advanced manufacturing jobs”, the Minister said.

According to Supashock’s Managing Director Oscar Fiorinotto, the ALHS 17 owns cutting-edge motion technology to create an integrated load handling solution for military use. By eliminating manual operations through the introduction of automated technology, a single soldier can operate the system. The ALHS 17 has several integral mechanical degrees of freedom that combine with a computer-assisted user interface, thus making the task of loading and unloading a container easy in all conditions. Rheinmetall, in its press release of 11 June, concluded that the cycle time of loading and unloading ISO containers or modules with the ALHS 17 is considerably faster than with in-service load handling systems.

Stefan Nitschke