Contributed Content, Edited for Clarity and Length

Thermal imagers make pictures from heat, also called infrared (IR) or thermal energy. They capture IR energy and use it to create images through digital or analogue video outputs, with the details defined by differences in temperature. Heat is a separate part of the electromagnetic spectrum from visible light: a camera that detects visible light will not see thermal energy, and vice versa.

Infrared camera detectors comprise an array of individual detector elements. Since energy wavelengths in the IR spectrum are longer than those of visible light, each IR detector element has to be correspondingly larger than elements on visible light detectors, in order to absorb the larger wavelength. As a result, a thermal camera usually has lower resolution (fewer pixels) than a visible light sensor of the same physical size.

Originally developed for surveillance and military operations, thermal cameras are now widely used for industrial applications such as building inspections, firefighting, autonomous vehicles, automatic emergency braking systems, industrial inspections, scientific research, and much more. These cameras come in a variety of form factors, from handheld cameras, through those mounted on unmanned aircraft, to scientific instruments destined for outer space.

Engineers developing products or systems incorporating thermal cameras need to have a clear understanding of the key design specifications, including scene dynamic range, field of view, resolution, sensitivity, and spectral range. Different cameras can excel at different functions, so engineers need to understand the tradeoffs between different types of thermal camera modules, as well as the impact those differences will have on final product performance.

One important specification, often overlooked at the expense of resolution, is thermal sensitivity – the specification that defines the smallest temperature difference a camera can detect. A thermal camera’s sensitivity will have a direct impact on image clarity and sharpness. Thermal devices measure sensitivity in milliKelvins (mK): the lower the number, the more sensitive the detector. Thermal sensitivity, also referred to as Noise Equivalent Temperature Difference (NETD), describes the smallest temperature difference observed: in effect, the lower the NETD value, the better the sensor will be at detecting small temperature differences. Integrators and developers should seek manufacturers offering NETD performance at the industry-standard 30 °C.

Increased sensitivity makes thermal imagers more effective at seeing smaller temperature differences – especially important in scenes with low thermal contrast and when operating in challenging environmental conditions like fog, smoke, and dust. Selecting a more entry-level, lower-cost thermal camera, featuring ‘acceptable’ to ‘satisfactory’ thermal sensitivity, leads to an end product that offers low contrast scenes, resulting in poorer image quality, reduced detection range, and limited situational awareness, compared to cameras with greater sensitivity. Devices with better thermal sensitivity are ideal for a wide variety of uses, from search and rescue through industrial inspection to security.

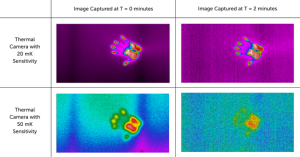

Comparisons of the image of a handprint taken at time zero and at two minutes, showing the difference between 20mK and 50mK sensitivity.

Comparisons of the image of a handprint taken at time zero and at two minutes, showing the difference between 20mK and 50mK sensitivity.

Cooled or Uncooled?

IR imaging cameras with a cooled detector provide distinct advantages compared to those with an uncooled detector. A cooled camera has an imaging sensor integrated with a cryocooler, which lowers the sensor temperature to cryogenic levels. This reduction is necessary to reduce thermally-induced noise to a level below that of the signal from the scene being imaged, and can result in significantly improved thermal sensitivity.

However, these improvements in performance come at a cost. Cooled IR cameras are generally larger, heavier, and more power-hungry. In addition to sacrificing SWaP, cooled cameras are significantly more expensive and subject to mechanical wear and tear that reduce the mean time to failure, as cryocoolers have moving parts with extremely tight mechanical tolerances that degrade over time, as well as helium gas that can slowly leak through seals.

Recent improvements in uncooled thermal sensors have brought sensitivity to better than 20mK – a vast improvement in sensitivity compared to legacy systems, potentially making uncooled LWIR cameras a viable option for a wide variety of new applications. Although tempting, it is important to note that uncooled IR thermal cameras cannot simply replace cooled thermal cameras. Product developers and system integrators need to consider additional requirements regarding imaging speed, spatial resolution, spectral filtering, and more.

A typical coastal surveillance image captured by a Boson+ camera.

A typical coastal surveillance image captured by a Boson+ camera.

For more information on thermal sensitivity, please see www.flir.com/bosonplus